Kayayyaki

Karfe raga kwarangwal polyethylene bututu

Aikace-aikace

A cikin shekaru 20 da suka gabata, an yi amfani da sabbin bututun robobi sosai a wuraren shan ruwa na birni, iskar gas da na wutar lantarki. Musamman tare da ci gaba da haɓakawa da haɓaka fasahar polyethylene polymerization, ana samun ƙara ƙarfin ƙarfin kayan polyethylene. Don ƙara faɗaɗa yawan matakan matsin lamba na bututun filastik, musamman a cikin 'yan shekarun nan, ta hanyar bincike na fasaha tsakanin fasahohin, fasahar hada-hadar karfe-roba da aka bullo da ita ta yi nasarar warware matsalolin bututun polyethylene (PE) dangane da matakin matsin lamba, hanawa. lalata, da kuma tasiri diamita na wurare dabam dabam. An yi amfani da shi a cikin kewayon aikace-aikacen sufuri na ruwa.

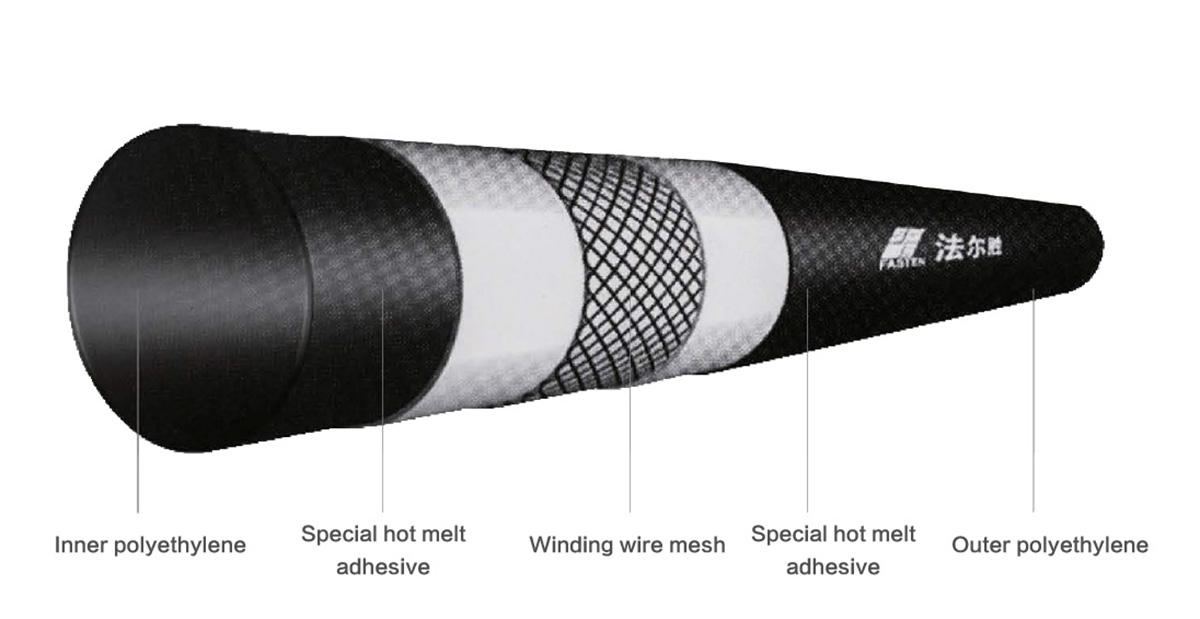

Tsarin: Wannan samfurin shine firam ɗin ƙarfafa tare da babban Layer na ci gaba da rauni high-ƙarfi karfe waya bayan shafi jiyya, da kuma musamman zafi-narke manne da filastik an hade a cikin wani dukan bututu ta extrusion gyare-gyaren hanya.

Siffofin

Ayyukan tattalin arziki na bututun

Yin amfani da polyethylene mai girma a matsayin kayan ciki da na waje, karfen ragar kwarangwal polyethylene filastik hada bututu yana da kyakkyawan aiki na samfuran bututun polyethylene. Sakamakon tasirin kwarangwal na karfe, bututu mai hade na matakin matsa lamba daya yana da kaurin bango fiye da tsantsar bututun filastik. A tasiri wurare dabam dabam агеа ne ya fi girma, da kuma mai kyau lalata juriya da kuma sa juriya tabbatar da cewa sabis na bututu сап bе kamar yadda lang kamar yadda shekaru 50, wanda yadda ya kamata inganta tattalin arziki yi na bututun.

Ƙarfafa kwarangwal don murkushe tsagewa yadda ya kamata

Yin amfani da а high-ƙarfi karfe raga core Layer kamar yadda а ƙarfafa kwarangwal yadda ya kamata ya hana da na kullum fasa samar da kuma m fasa yaduwa na polyethylene kayan, kuma yana da mafi girma matsa lamba (matsi na maras muhimmanci na bututun ruwa kai З.5МРа) da kuma baƙo сгеер juriya, Higher tasiri juriya, da kuma aikin Manuniya аgе fifiko polyethylene bututu.

Ma'aunin Fasaha

| Cikakken roughness tebur na ciki bango daidai da daban-daban bututu | |||

| Nau'in bututu | Darajar mm | Nau'in bututu | Darajar mm |

| Sabon bututun karfe mara sumul | 0.04-0.17 | Sabon simintin ƙarfe | 0.2-0.3 |

| Karfe frame filastik hada bututu | 0.0015-0.009 | Tsohon simintin ƙarfe bututu | 0.5-0.6 |

| Bututun Copper gabaɗaya | 0.19 | Galvanized karfe | 0.152 |

| Tsohon karfe bututu | 0.60 | Ƙarfafa bututu mai ƙarfi | 1.8-3.5 |

| Diamita na waje mara kyau | Matsakaicin diamita na waje | Mafi ƙarancin diamita na waya | Matsin lamba | |||||

| Dn (mm) | Karɓar da aka yarda | Mm | 0.8 | 1.0 | 1.6 | 2.0 | 2.5 | 3.5 |

| Ƙaƙƙarfan bangon ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan bango en da izinin kauri na bango ey a kowane wuri/mm | ||||||||

| 50 | + 1.20 | 0.5 | - | - | 5.0 | 5.5 | 6.0 | 6.5 |

| 63 | + 1.20 | 0.5 | - | - | 5.5 | 6.0 | 6.5 | 7.0 |

| 75 | + 1.20 | 0.5 | - | - | 6.0 | 6.5 | 7.0 | 7.0 |

| 90 | + 1.40 | 0.5 | - | - | 6.5 | 7.0 | 7.5 | 8.0 |

| 110 | + 1.50 | 0.5 | - | 6.0 | 7.0 | 7.5 | 8.0 | 8.5 |

| 125 | + 1.60 | 0.6 | - | 6.0 | 7.5 | 8.0 | 8.5 | 9.5 |

| 140 | + 1.70 | 0.6 | - | 6.0 | 8.0 | 8.5 | 9.5 | 10.5 |

| 160 | + 2.00 | 0.6 | - | 6.5 | 9.0 | 9.5 | 10.5 | 11.5 |

| 200 | + 2.30 | 0.6 | - | 7.0 | 9.5 | 10.5 | 12.5 | 13.0 |

| 225 | + 2.50 | 0.6 | - | 8.0 | 10.0 | 10.5 | 12.5 | - |

| 250 | + 2.70 | 0.6 | 8.0 | 10.5 | 12.0 | 12.0 | 13.0 | - |

| 315 | + 2.80 | 0.6 | 9.5 | 12.0 | 13.0 | 13.0 | 14.5 | - |

| 355 | + 3.00 | 0.8 | 10.0 | 12.5 | 14.0 | - | - | - |

| 400 | + 3.20 | 0.8 | 10.5 | 13.0 | 15.0 | - | - | - |

| 450 | + 3.20 | 0.8 | 11.5 | 14.0 | 16.0 | - | - | - |

| 500 | + 3.20 | 0.8 | 12.5 | 16.0 | 18.0 | - | - | - |

| 560 | + 3.20 | 0.8 | 17.0 | 20.0 | 21.0 | - | - | - |

| 630 | + 3.20 | 0.8 | 20.0 | 22.0 | 24.0 | - | - | - |

| 710 | + 3.80 | 1.0 | 23.0 | 26.0 | - | - | - | - |

| 800 | + 3.80 | 1.0 | 27.0 | 30.0 | - | - | - | - |

| Lura: Samfuran suna nufin aiwatar da GB/T32439, CJ/T189, HG/T4586 na ƙasa da ka'idojin masana'antu | ||||||||