Kayayyaki

Perforated karfe tsiri PE bututu Don gas

Aikace-aikace

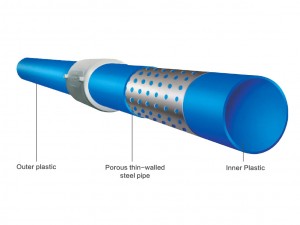

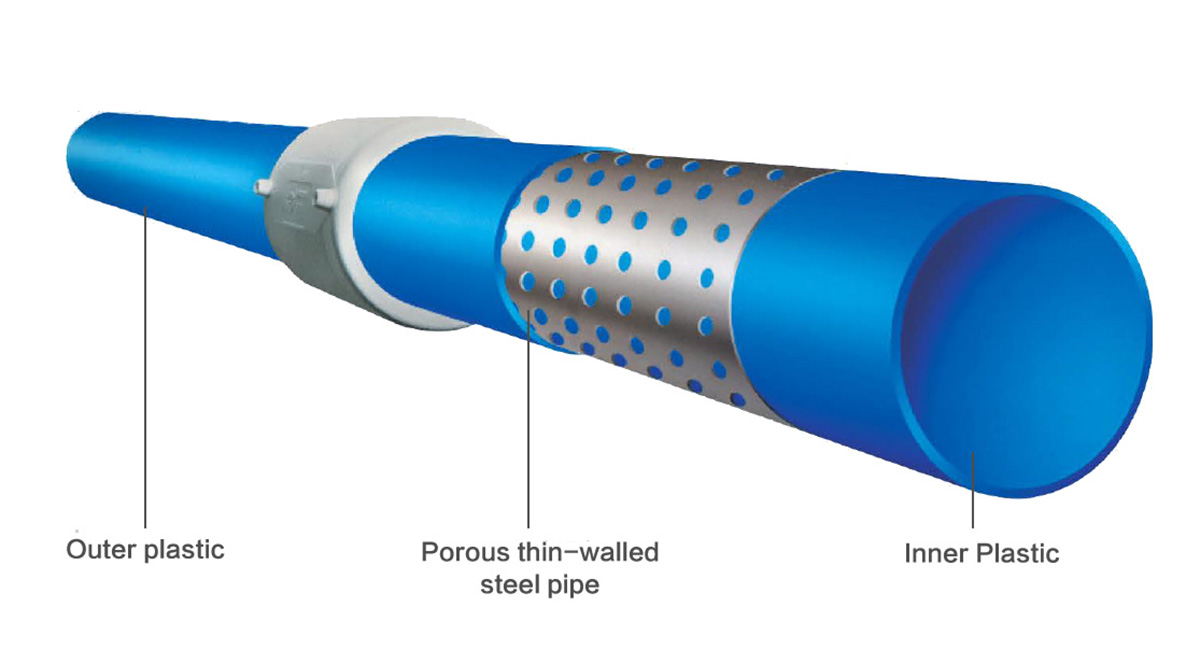

Perforated karfe tsiri polyethylene composite bututu da aka yi da sanyi birgima tsiri karfe da thermoplastics a matsayin albarkatun kasa, da porous bakin ciki mai bango bututu kafa ta argon baka butt waldi ko plasma karkace waldi ana amfani da matsayin ƙarfafawa. Yadudduka na waje da na ciki su ne na'urorin haɗe-haɗe na thermoplastics. Wani sabon irin hadaddun matsa lamba bututu, Saboda porous bakin ciki-banga karfe bututu ƙarfafa aka nade a ci gaba da thermoplastic, wannan hadadden bututu ba kawai shawo kan Game da shortcomings na karfe bututu da filastik bututu, amma kuma yana da rigidity na karfe bututu da lalata. juriya na filastik bututu. Magani ce ga masana'antun man fetur da sinadarai. Bututun bututu ne da ake bukata cikin gaggawa na manyan bututu masu tsayi da matsakaici a cikin fagagen magunguna, abinci, ma'adinai, gas da sauran filayen. Har ila yau, ci gaban fasaha ne na juyin juya hali don warware babban bututun gine-gine da samar da ruwan sha na birni. Wani sabon nau'in bututun mai hade ne a cikin 21stkarni.

Siffofin

Ayyukan tsafta

Indexididdigar tsabta da aminci na bututun da aka rutsa da fasinja na filastik filastik sun dace da bukatun GB9687 "Hygienic Standard for Polyethylene Molded Products for Food Packaging" da GВ/Т17219 "Tsarin Ƙididdiga don Kayayyakin Rarraba Ruwa na Sha kuma akan Kayayyaki da Kayayyakin Kariya". Shi ne mafi kyawun madadin bututun galvanized da bututun simintin ƙarfe.

Ganuwar ciki mai laushi da aikin wurare dabam dabam

Bangon ciki na ragar bel ɗin filastik mai haɗawa da bututu yana da santsi sosai, kuma cikakkiyar roughness shine kawai 1/20 na na bututun ƙarfe. Ikon isarwa a ƙarƙashin yanayi guda yana da kusan 30% sama da na bututun ƙarfe.

Ma'aunin Fasaha

| Girman ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙima: cika buƙatun ma'aikatar ginin ma'aunin CJ/T181-2003 | |||||

| Diamita na waje da karkacewa | Kaurin bango mara kyau da karkata | Daga zagaye | Matsin lamba | Mafi ƙarancin ƙimar S | Tsawo da karkata |

| Dn (mm) | En (mm) | Mm | Mpa | Mm | mm |

| 50 + 0.5 0 | 4.0+0.5 9 | 1.0 | 1.0 | 1.5 | 6000+200 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5 + 0.6 0 | 1.26 | 1.0 | 1.5 | |

| 75 + 0.7 0 | 5.0 + 0.7 0 | 1.5 | 1.0 | 1.5 | |

| 90 + 0.9 0 | 5.5 + 0.8 0 | 1.8 | 1.0 | 1.5 | |

| 110+1.0 | 6.0 + 0.9 0 | 2.2 | 1.0 | 1.5 | |

| 140+1.1 0 | 8.0 + 1.0 0 | 2.8 | 1.0 | 2.5 | |

| 160+1.2 0 | 10.0 + 1.1 0 | 3.2 | 1.0 | 2.5 | |

| 200 + 1.3 0 | 11.0 + 1.2 0 | 4.0 | 1.0 | 2.5 | |

| 250+1.4 0 | 12.0 + 1.3 0 | 5.0 | 0.8 | 3.5 | |

| 315+1.6 0 | 13.0 + 1.4 0 | 6.3 | 0.8 | 3.5 | |

| 400+1.6 0 | 15.0 + 1.5 0 | 8.0 | 0.8 | 3.5 | |

| 500+1.7 0 | 16.0 + 1.6 0 | 10.0 | 0.6 | 4.0 | |

| 630+1.8 0 | 17.0 + 1.7 0 | 12.3 | 0.6 | 4.0 | |

| Lura: Matsakaicin matsi na bututu mai haɗaka shine matsakaicin matsakaicin da aka ba da izinin bututun don jigilar ruwa a 20 ° C. Idan yanayin zafi ya canza, ya kamata a gyara matsa lamba na aiki bisa ga ma'aunin zafin jiki na kayan daban-daban. S darajar: nisa daga diamita na waje na ƙarfafawa zuwa farfajiyar waje na bututu. | |||||

| Bukatun aikin jiki da na inji | ||

| Aikin | Ayyuka | |

| Ƙunƙarar zobe, KN/m2 | >8 | |

| Tsawon tsayi (110 ° C, kula da 1h) | <0.3% | |

| Gwajin hydraulic | Zazzabi: 20 ° С; Lokaci: 1h; Matsin lamba x2 | Ba karya ba |

| Zazzabi: 80 ° С; Lokaci: 165h; Matsin lamba: matsa lamba mara kyau x2x0.71 (matsalar raguwa) | ||

| Gwajin gwajin fashewa | Zazzabi: 20°C, fashewar matsa lamba≥matsi mara kyau x3.0 | Fashewa |

| Lokacin shigar Oxidation (200°C), min | >20 | |

| Mai jurewa ga saurin faɗaɗa damuwa (80°C, 4.0Mpa)/h | > 1000 | |

| Juriya na yanayi (bayan bututun ya karɓi≥3.5GJ/m2kuzarin tsufa) | Haɗu da buƙatun abubuwa 2,3 da 4 a cikin wannan tebur, kuma suna iya kula da aikin walda mai kyau | |